Manufacturing of Standard, High-Precision, and Large-Scale Components

We offer comprehensive machining services for standard, precision, and large components, including custom gears with modern equipment and strict quality control.

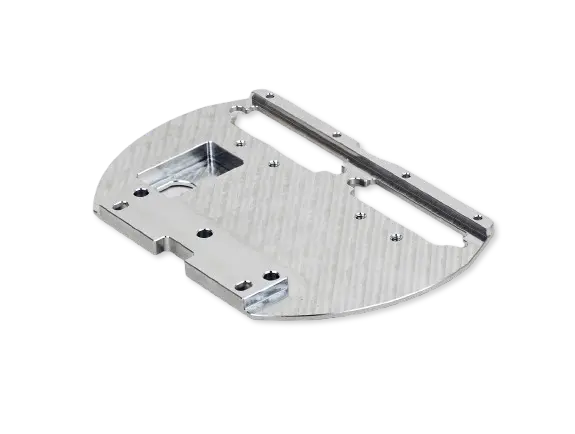

We manufacture standard metal parts in series with typical sizes and tolerances, leveraging a versatile machine park for efficient large-batch processing.

We produce series of components with tight tolerances, form accuracy, and surface finish. Dimensional repeatability within IT6-IT7 and geometric control aligned with ISO 2768-fH, ISO 286, ISO 1101.

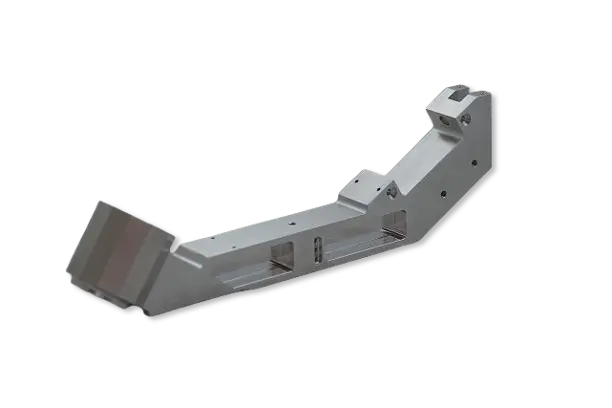

A strategic focus area with capacity to machine large parts such as rods and shafts up to 2 meters diameter and 16 meters length, including custom hydraulic cylinder parts.

Delivering precision machining solutions across diverse industrial sectors

Whether you need prototype support or full-scale production, we offer fast lead times, expert engineering, and reliable results.

Get In TouchWe produce custom gears of various sizes and complexities, including large gears up to several meters diameter, tailored to your specifications.

We use a broad range of metals and alloys compliant with international standards and customer specifications.

Quality control is integral at every stage to guarantee reliability and compliance with high-demand sectors.