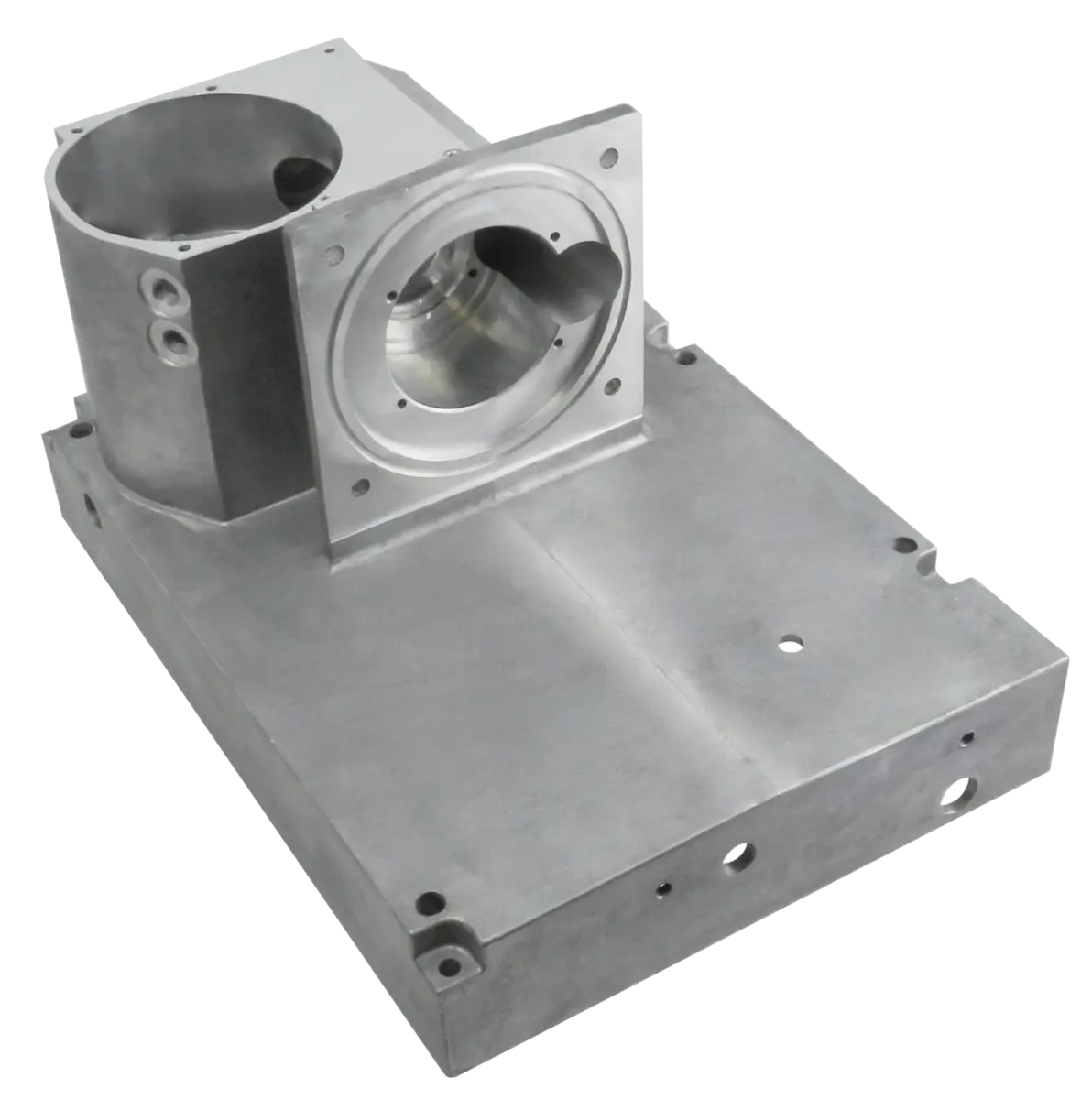

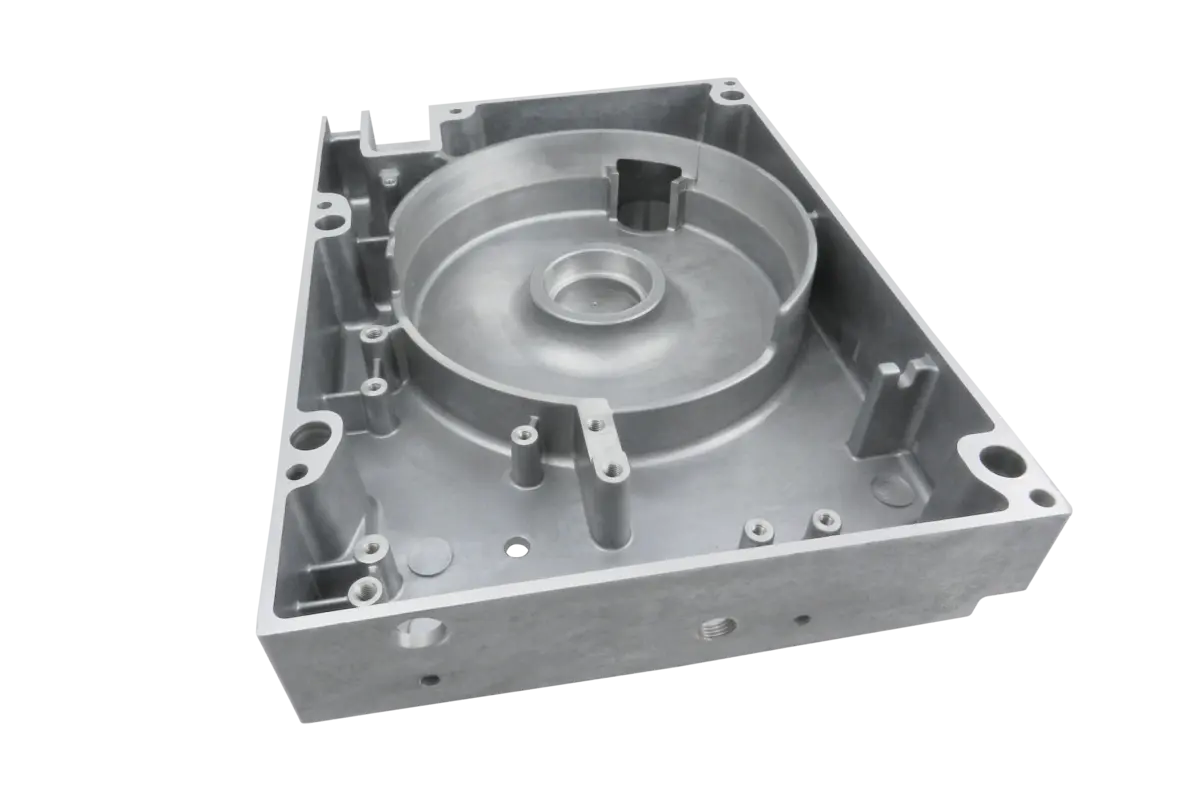

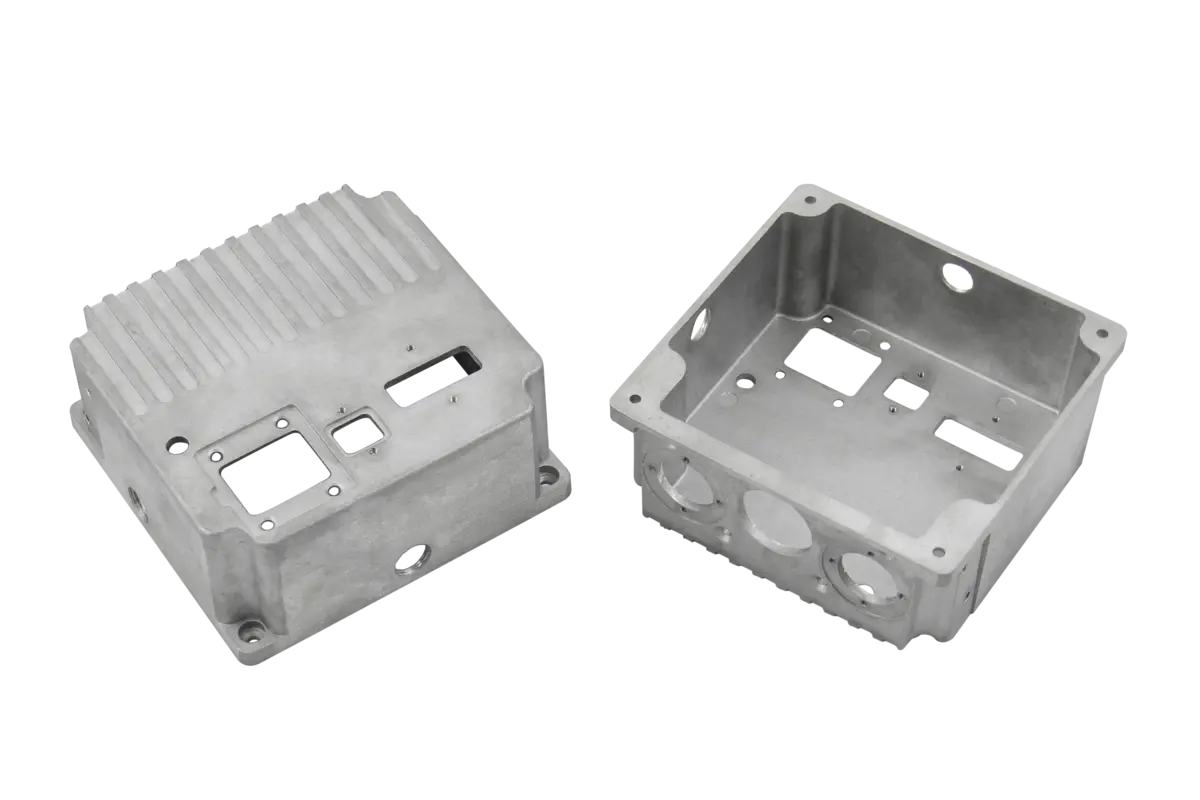

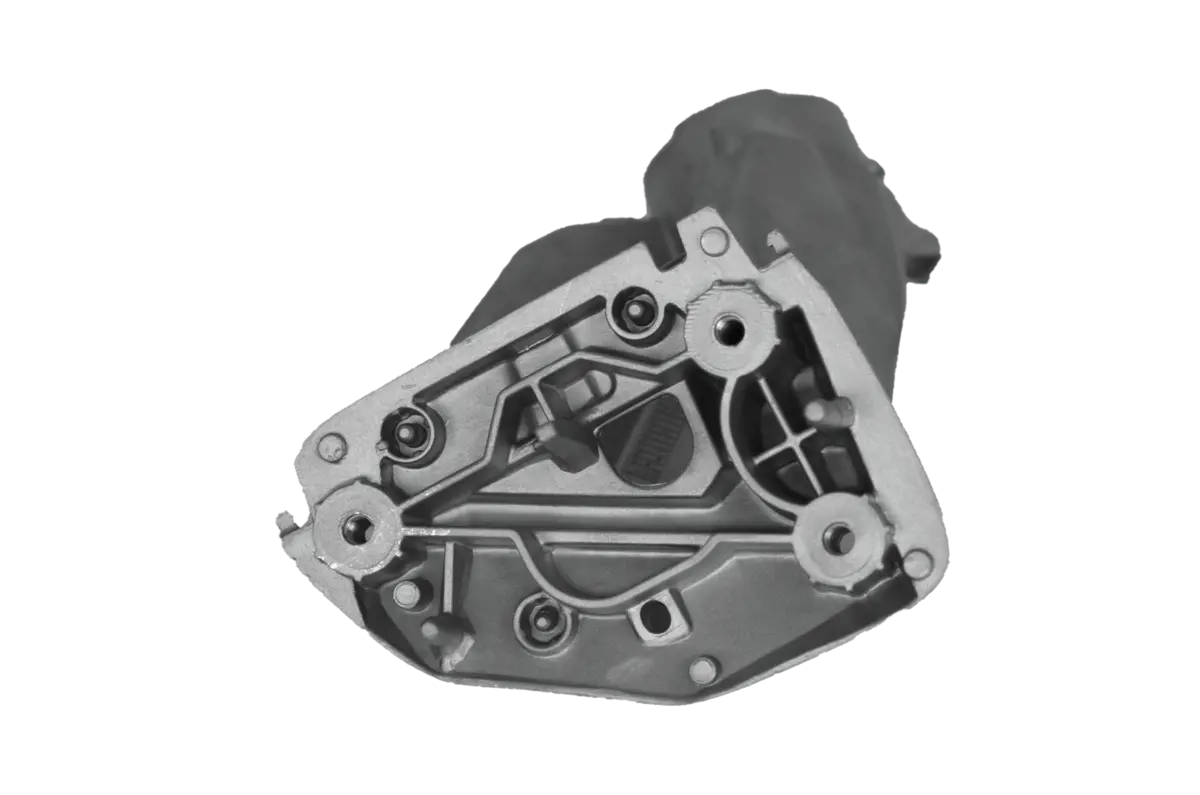

Precision, Efficiency, and Exceptional Surface Quality

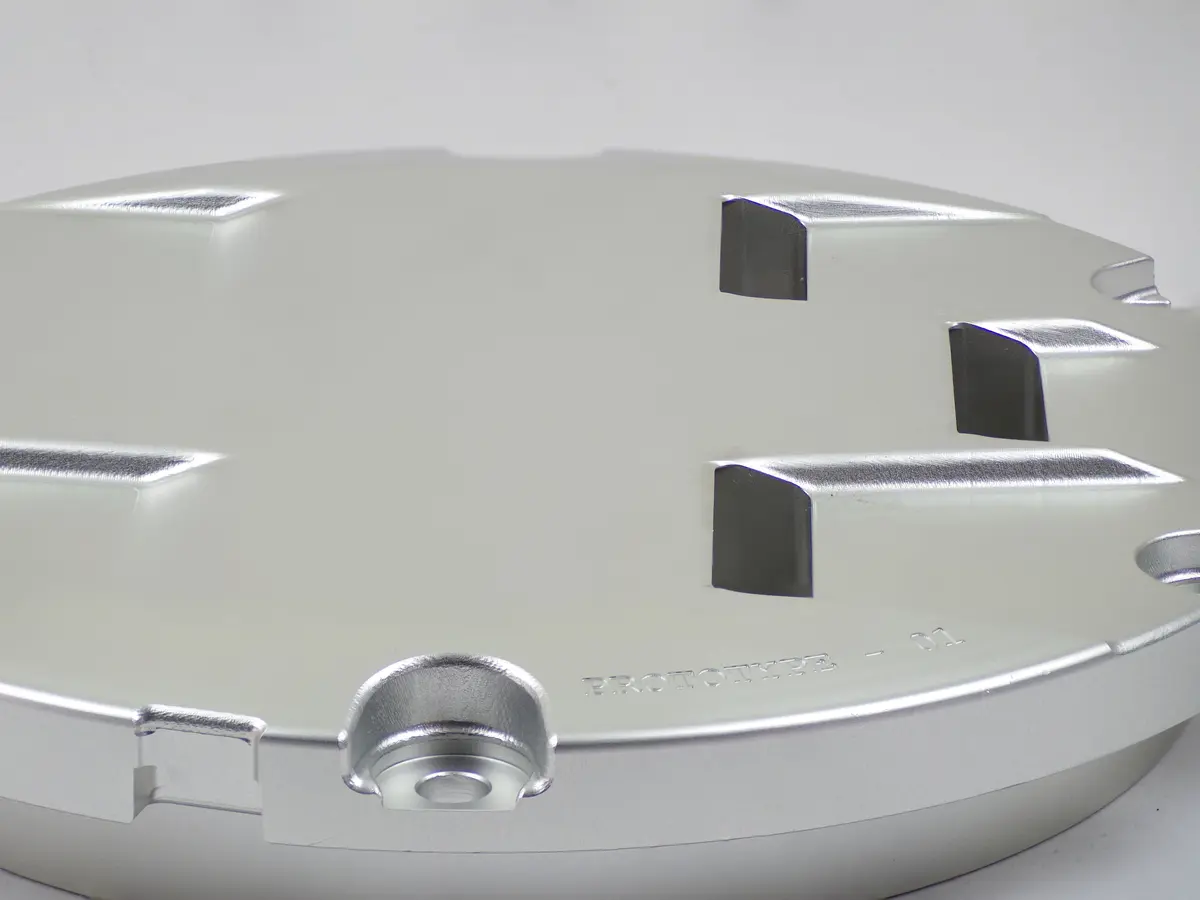

Looking for high-volume production of complex aluminum parts with superior dimensional accuracy? Our High-Pressure Die Casting (HPDC) technology delivers exceptional results for demanding applications.

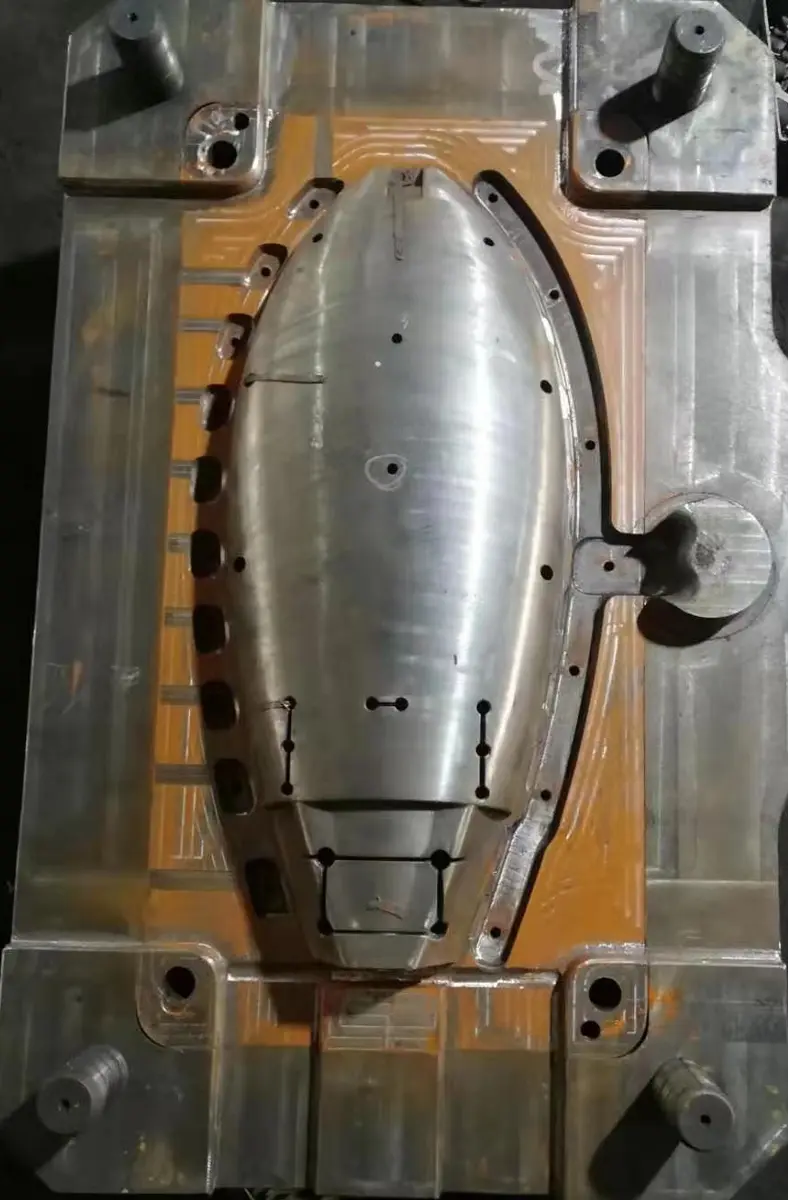

Advanced mold design and manufacturing capabilities for optimal die casting results

Contact us for a consultation and quote.

Tell us about your requirements — we'll provide the most efficient HPDC solution.

Delivering high-pressure die casting solutions across diverse industrial sectors