Complete range of gear, planetary, axial-piston, and radial-piston hydraulic motors designed for interchangeability

Compatible replacements aligned with widely used M+S and Danfoss footprints for broad application coverage.

Designed for interchangeability with specifications used by Bucher, Danfoss, and M+S in traction and drive applications.

Cost-effective alternatives referencing PSM Hydraulic and Danfoss configurations for dependable duty cycles.

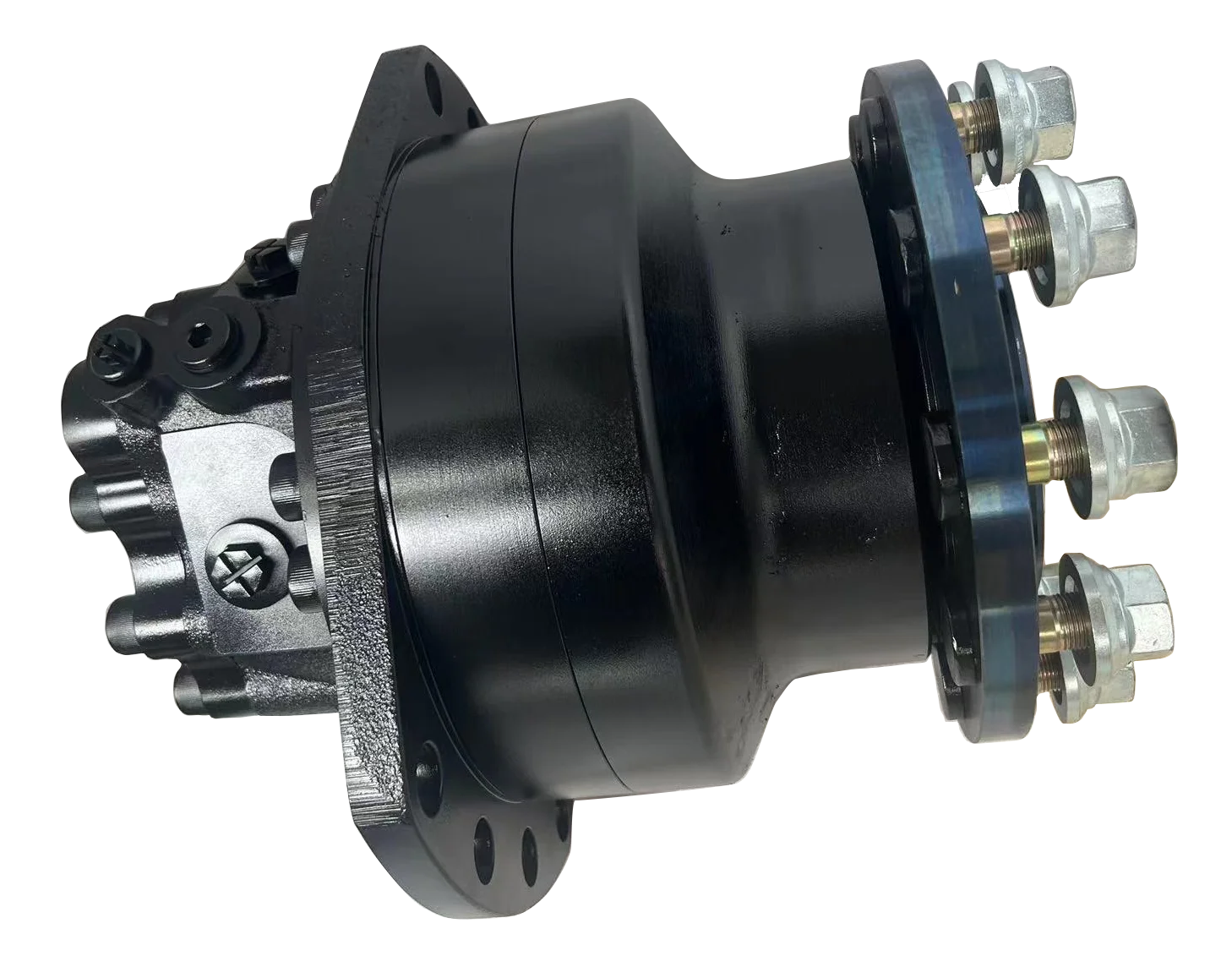

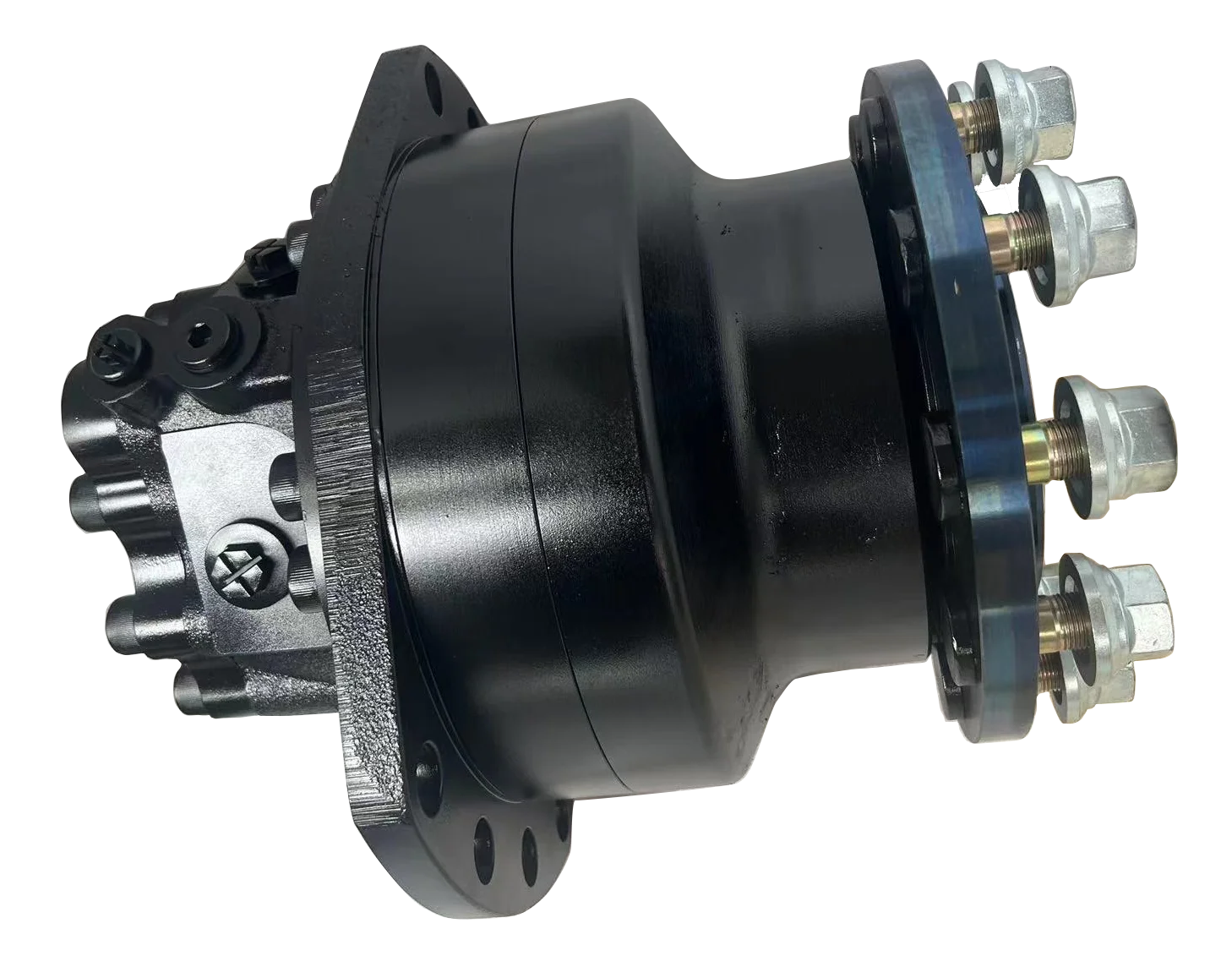

High-torque solutions aligned to Poclain-type interfaces; EMS and EMCR series compatibility is available on request.

Proven, application-oriented hydraulic solutions across multiple industries

Proven, application-oriented hydraulic solutions for construction, agriculture, material handling, marine, and infrastructure projects.

Simplify maintenance and reduce downtime when replacing imported units with our compatible alternatives.

Supported by modern engineering and production practices geared for repeatable results and reliable performance.

Comprehensive support from selection to installation

Model cross-reference and replacement recommendations for installed fleets to ensure perfect compatibility.

Support with drawings and mounting/porting checks to confirm form-fit-function before delivery.

Access to product catalogs, including EMS/EMCR radial-piston ranges and A10V pump families, for fast technical validation.

Complete selection of hydraulic motors and pumps for every industrial need

Axial and radial configurations for maximum efficiency

Industry-leading specifications across our entire product range

Powering industries worldwide with reliable hydraulic solutions

Leading expertise in hydraulic motor and pump solutions

High-grade materials and precision manufacturing for maximum durability

"Built to last in demanding conditions"

Tailored solutions for specific application requirements

100% CustomizableISO, DIN, SAE compliance with marine and ATEX certifications

"Certified for global markets"

Extensive inventory and express manufacturing available

24-Hour ShippingComplete range of gear, planetary, axial-piston, and radial-piston hydraulic motors designed for interchangeability

Compatible replacements aligned with widely used M+S and Danfoss footprints for broad application coverage.

Designed for interchangeability with specifications used by Bucher, Danfoss, and M+S in traction and drive applications.

Cost-effective alternatives referencing PSM Hydraulic and Danfoss configurations for dependable duty cycles.

High-torque solutions aligned to Poclain-type interfaces; EMS and EMCR series compatibility is available on request.

Powering diverse industrial sectors with specialized hydraulic solutions

Engineering excellence meets practical application

Delivering substantial torque even at low speeds while saving installation space.

Wide operating range, precise positioning, and easy reversing capability.

Proven performance under heavy loads, vibration, dust, and moisture with long service life.

Compatible with various hydraulic systems and suitable for mobile, industrial, and marine applications.

Industry-leading performance parameters

Our engineering team is ready to help you select the perfect hydraulic motor solution for your application

Engineered for reliable performance across mobile and industrial applications

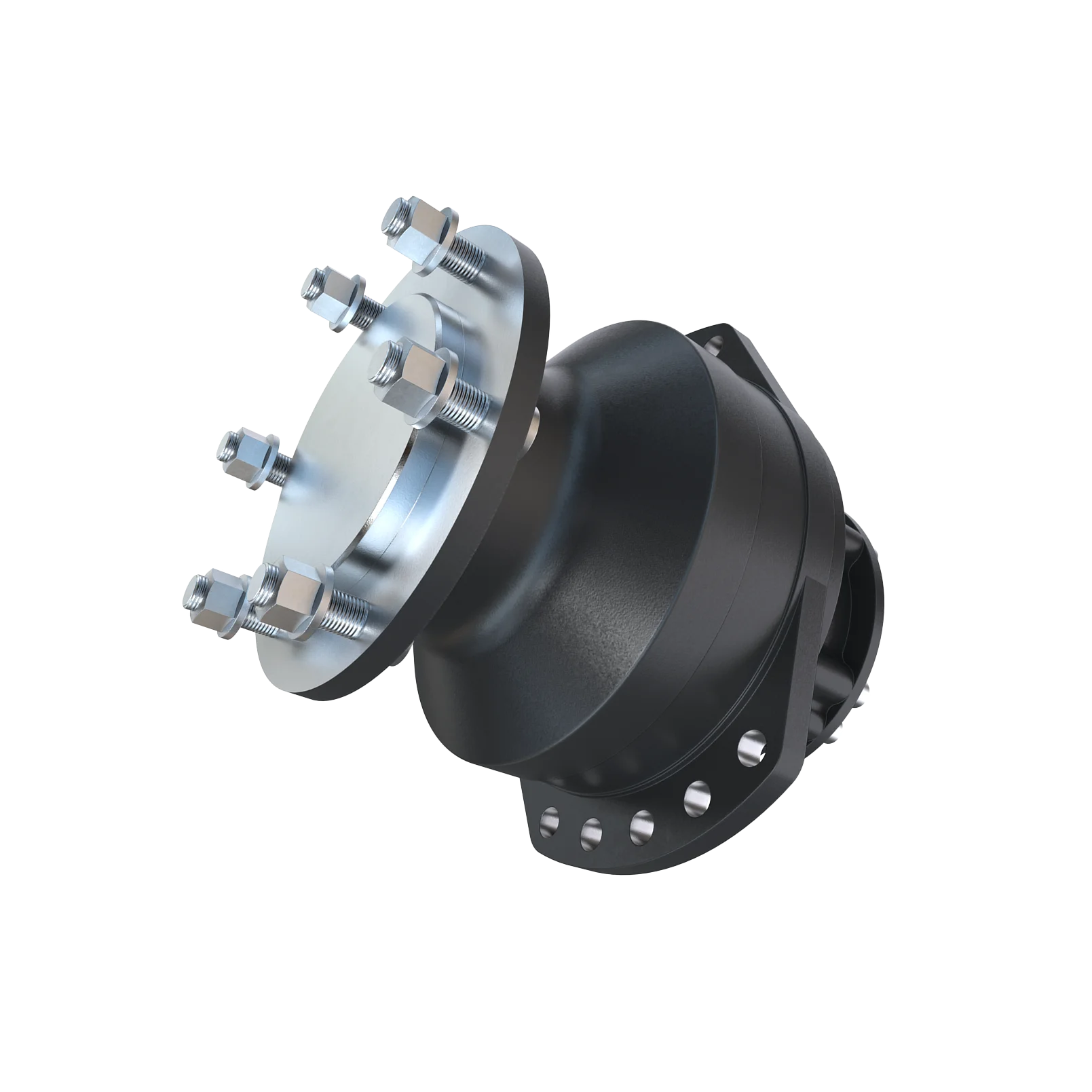

We supply gear, planetary, axial-piston, and radial-piston hydraulic motors with specifications aligned for interchangeability in common equipment platforms, offering compatible replacements for leading European brands.

Complete range of gear, planetary, axial-piston, and radial-piston hydraulic motors designed for interchangeability

Compatible replacements aligned with widely used M+S and Danfoss footprints for broad application coverage.

Available in multiple configurations including 2, 3, 4, 5, and 6-speed versions plus wheel drive motors.

Fixed and variable displacement models compatible with Rexroth A2F, A6V, and A10V series.

High-torque solutions for demanding applications, compatible with leading European designs.

Engineering excellence meets practical application

Delivering substantial torque even at low speeds while saving installation space.

Wide operating range, precise positioning, and easy reversing capability.

Proven performance under heavy loads, vibration, dust, and moisture with long service life.

Compatible with various hydraulic systems and suitable for mobile, industrial, and marine applications.

Explore our range of hydraulic motors and components manufactured with highest quality standards

Powering diverse industrial sectors with specialized hydraulic solutions

Our engineering team is ready to help you select the perfect hydraulic motor solution for your application

Industry-leading performance parameters

State-of-the-art production facilities equipped with modern CNC machining centers, precision turning machines, and advanced quality control systems ensure every motor meets the highest international standards.

Motors produced annually with consistent quality

Certified quality management system

Advanced machining centers for precision manufacturing

Every motor tested before delivery

Rigorous testing and inspection procedures guarantee reliable performance

Every motor tested to 500 bar to ensure structural integrity and leak-proof operation under extreme conditions

Flow rate, torque output, and efficiency validated against specifications on dedicated test benches

Batch numbers and quality certificates ensure complete tracking from raw materials to finished product

24-month standard warranty coverage with extended options available for added peace of mind

Incoming material verification and in-process dimensional checks using precision measurement equipment

Regular audits, employee training, and feedback loops drive ongoing quality enhancements